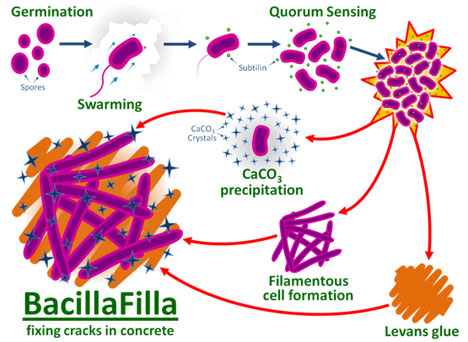

Imagine buildings that never need to be repaired, streets that heal their own cracks, and sidewalks that morph back into perfect condition after buckling and breaking. A smart bacteria might usher in all of those things and more by helping concrete seal on its own after cracking up.

The self-healing concrete would be particularly useful in places where earthquakes are common and tend to create structural damage that has historically proven very difficult to repair. Rather than razing the buildings as in the past, we could continue to use them as the damage is quickly and easily repaired. Worried about crazy concrete-secreting bacteria taking over and paving the planet? Have no fear: the bacteria would have built-in safety measures that would allow them to work their magic only in structural cracks and would cause them to self-destruct if they ventured outside of the intended target.

Another way of self-healing concrete is developed by Delft University of Technology. They developed asphalt pavements:

The bitumen bonds can be repaired once and again, for several times, by making asphalt electrically conductive. Because asphalt concrete is not an electrically conductive material, steel wool fibers have been added. These are connected inside the asphalt concrete and create small circuits. When this new type of asphalt is heated with induction energy, the bitumen melts and that holds the road together. |

No comments:

Post a Comment